Three digital levers to hit CSRD waste metrics

A practical playbook to capture, verify, and report ESRS E5 waste data with real time tracking, EPR evidence, and design intelligence.

The audit clock is ticking. The Corporate Sustainability Reporting Directive (CSRD) raises the bar on how companies measure and report waste. European Sustainability Reporting Standards (ESRS), E5 asks for more than annual totals. It asks for auditable evidence of how materials move, what happens to them, and whether design choices are reducing waste at the source. The good news is that three digital levers can get you most of the way there in one to two quarters.

Why CSRD waste reporting is hard in practice?

Many teams still rely on spreadsheets, quarterly vendor emails, and PDF weighbridge slips. Sites track different fractions with different units. Contractors use non-standard codes for treatment. EPR data lives in a separate universe from plant operations. The result is late, inconsistent, and hard to audit. CSRD expects comparable, decision-useful information. That means digitised capture, harmonised taxonomies, and traceable flows.

Lever 1: Real time site inventory and routing

Objective: establish a single source of truth for waste generation and fate at each facility.

How it works:

- Connecting weighbridges and floor scales to a central database (IoT).

- Using QR or barcode tags on containers and pallets to identify fraction, source line, and destination.

- Replacing paper consignment notes with e-manifests that carry all required attributes.

- Capturing contractor arrival, handoff, and dispatch with time stamps and driver IDs.

- Standardising taxonomies so every record maps to ESRS E5 categories, hazardous flags, and treatment codes.

What you get?

- Mass Balancing

- Daily visibility of volumes by fraction, site, and destined treatment.

- Automated checks against unusual weights, duplicate tickets, and missing handoffs.

- Month-end close that takes hours instead of days.

- Evidence suitable for audit sampling because every data point has provenance.

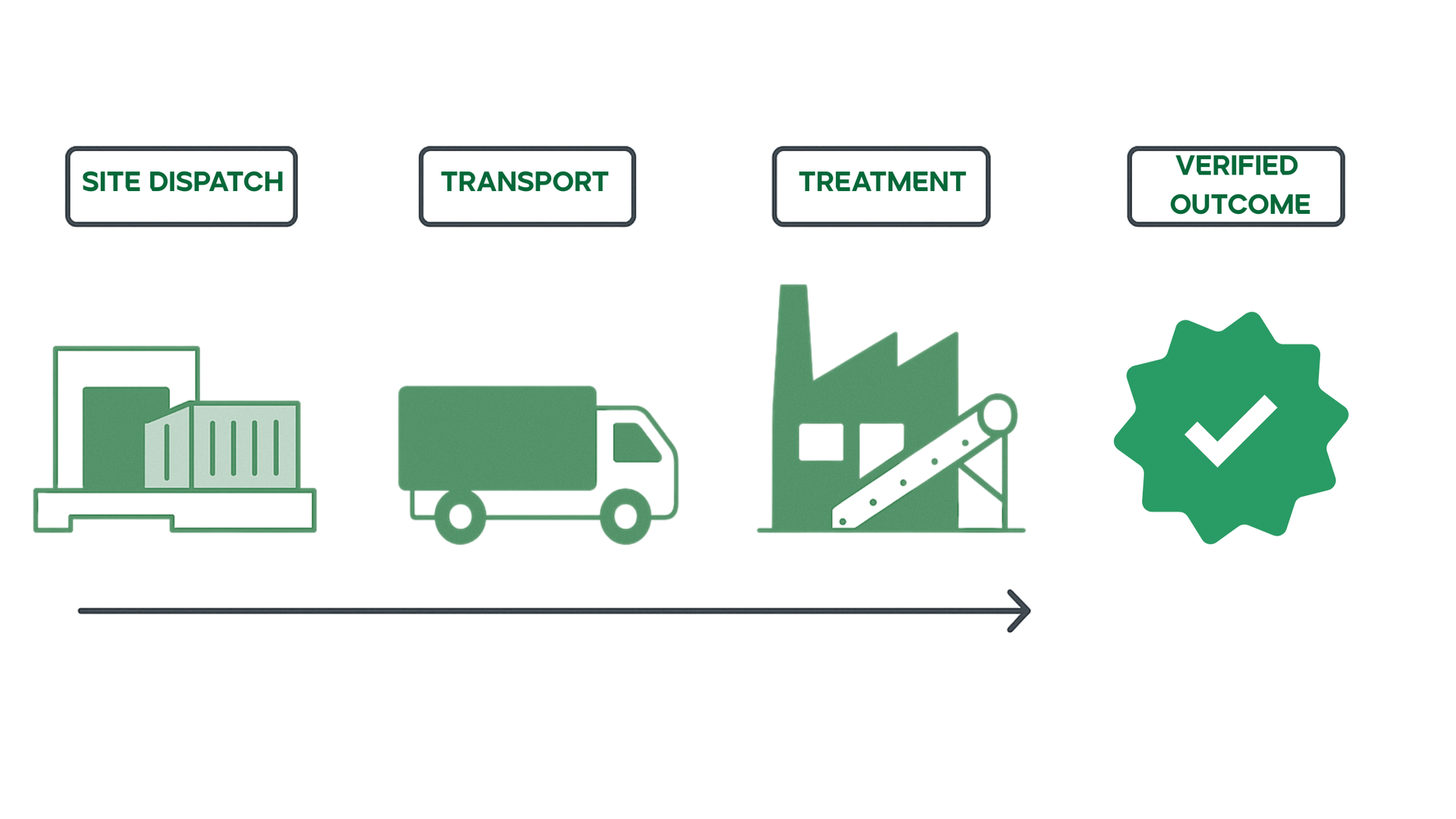

Lever 2: Value chain traceability with producer responsibility proof

Objective: connect operational data with market obligations so CSRD numbers reflect reality across the chain.

How it works:

- Ingesting producer responsibility records such as invoices, declarations, and verified recovery statements.

- Linking recycler delivery notes, mass-balance statements, and material certificates to specific outbound loads.

- Recording cross-border shipments with the required permits and confirmations.

- Reconciling operations so the same kilo is not counted twice, and treatment codes align.

What you get?

- A verified chain of custody from site to treatment.

- Recovery and recycling rates you can defend, supported by third party documents.

- A clear view of fees paid versus outcomes achieved, which informs design decisions and budget allocations.

Lever 3: Design and material intelligence

Objective: shift the focus upstream so you generate less waste and design for recovery.

How it works:

- Connecting bills of materials and packaging specifications to recyclability rules and restricted substances lists.

- Flagging formats that are hard to sort or recycle and proposing alternatives.

- Tracking recycled content, reuse, share, and phase-out of problematic components.

- Modelling the impact of a design change on waste generation and CSRD KPIs before launch.

What you get?

- Fewer hard-to-treat formats entering operations.

- Quantified progress on reduction, recycled content, and design for circularity.

- Product level insights that translate into site level improvements.

Try our Circularity Checklist.

Not sure if your systems can stand up to CSRD scrutiny? Our quick checklist helps you benchmark circularity readiness across supply chain, product stewardship, and data proof points. It’s a fast way to spot reporting gaps before auditors do.

Access the checklist here.

HOW GFS HELPS?

GFS supports delivery from policy to the post-consumer system. We design compliant frameworks, implement producer responsibility with partners, and provide verifiable data traceability for collection, sorting, and recovery. PROcycle and PROcess connect obligations, field operations, and audit-ready reporting so you can move from treaty or regulation text to working systems.

If you want a practical path to credible CSRD waste reporting, we are ready to help.